Portable X-ray fluorescence (pXRF) and X-ray diffraction (pXRD) analyzers can provide significant cost and operational benefits to active mining operations. Many decisions must be made at the mine site based on geochemical and mineralogical analysis of a wide variety of sample types. pXRF and pXRD can improve the forecasting of many important rock parameters such as grade, hardness, alteration, and lithology that all impact the recovery of the economic metals being mined. These analyzers play a key role in decision-making and help optimize operational efficiency in many ways, including underground mining, open-pit mining, the production process, the laboratory, and environmental applications.

Improve the Efficiency of Your Mining Operation

- Accurately and rapidly define ore/waste boundaries from blast holes and underground face, drive, and blast samples

- Understand the geochemical and mineralogical dimensional characteristics of the deposit

- Prevent problematic materials (arsenic, talc, or clay rich) from going to the mill

- Reduce lead time associated with grade control sample analysis

- Increase sampling numbers/density within the grade control envelope

- Reduce mine site analytical costs and reduce the load of the mine site laboratory

- Improve blending strategies with real-time analysis of run-of-mine (ROM) material

- Optimize milling and crushing residence times based on analysis of silicon (Si) as a proxy for quartz

Improve Recovery of Minerals

- Analyze feeds and tailings to optimize flow sheet

- Understand the presence of floating clays in feeds and mid cons

- QA/QC on concentrates

- Copper (Cu) in liquids in solvent extraction-electrowinning (SX/EW) operations

- Analyze arsenic (As) to inform cyanide leach specifications

- Sulfur (S) analysis in feed to inform sulfide/oxide ratios

- Inform flux adjustments and penalty elements in precipitates and bullion

- Analyze smelted material for process control

- Gold (Au) and calcium (Ca) in activated carbon

- Uranium (U) of in-situ leaching (ISL) liquids

Easy Quantification Using XRF

- Reduce reliance on wet chemical techniques

- Reduce load on limited laboratory resources (time and equipment)

- Reduce analytical turnaround time from hours to minutes

- Baseline mine site environmental monitoring and sulfur (S) in waste rock to predict acid mine drainage (AMD)

- Cost savings associated with reduction in lab technician times and reagents used

- Improved safety through less use of hydrofluoric and nitric acids: reduction in skin burns and lead fumes associated with the fire assay process

Types of Mines Using Olympus pXRF and pXRD for Grade Control

- Base metals: copper (Cu), lead (Pb), zinc (Zn), nickel (Ni), tin (Sn), tungsten (W), molybdenum (Mo), tantalum (Ta), antimony (Sb), manganese (Mn), chromium (Cr), niobium (Nb), cobalt (Co)

- Bulk commodities: iron ore, phosphate, bauxite, coal

- Mineral sands: titanium (Ti) and zirconium (Zr)

- While not the primary tool for grade control, pXRF and pXRD are used extensively in gold (Au) and silver (Ag) mining and lithium (Li) production

Quantifying Copper Grade and Mineralogy Using Olympus pXRF and pXRD

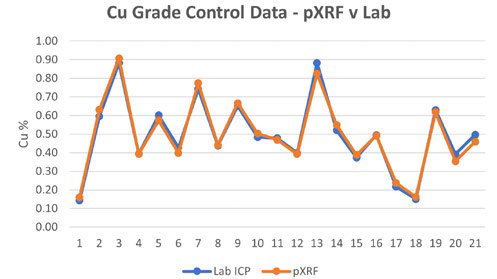

(Figure 1). Analysis of grade control pulp samples from an active Cu mine using pXRF

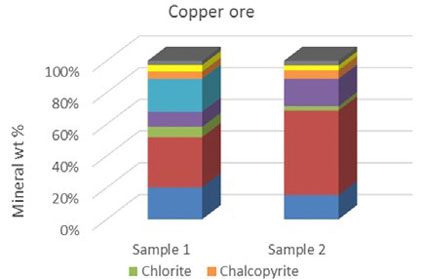

(Figure 2). pXRD analysis of ore showing similar copper concentrations (chalcopyrite) but appreciably more chlorite, which will negatively impact the flotation process

Benefits of Vanta™ XRF Analyzers

Vanta handheld XRF analyzers enable you to analyze a range of materials quickly and nondestructively at the mine site. Benefits include:

- Continuous operation at high temperatures: Up to 50°C (122°F)

- IP55/IP54 rated: Withstands dirt, dust, and rain to protect against hazards in challenging environments

- Drop tested (MIL-STD-810G): Protects against falls and reduces the need for costly repairs

- Cloud-technology enabled: Access and share data across multiple platforms from any location

Benefits of BTX™ III and TERRA™ II pXRD

- Small Sample: Requires only 15 mg of sample

- Easy Sample Preparation: Does not require a skilled technician

- Fast Acquisition Time: Obtain results in only a few minutes

- Stand-Alone Instrument: No need for water cooling or a large, external power source

- No Ongoing Service Requirements: XRD can be performed regularly with minimal downtime

- Portable: Battery-operated, rugged design with no moving parts